More information about the stepper motors:

Principle

of operation ;

Stepper motors

The two phase bipolar and

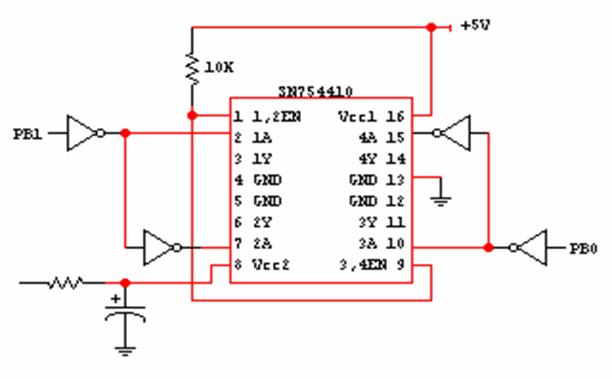

four-phase unipolar motors are available in the lab. To drive the steppers one can use the

SN754410 quadruple half-h drive; (the pdf file describing this ic is sn754410.pdf). The stepping sequence for both types of

motors can be the same as long as the connections are done properly, (please

see the following diagram).

The test program for driving

the steppers is provided (stepper.asm).

Motor voltage 5 – 15 V PP4 PP2 PP1 PP0

![]()

![]()

![]()

![]()

For the 2-phase bipolar motors

- connect the blue wire to 1Y, red wire to 2Y, white wire to 3Y, and yellow to

4Y.

For the 4-phase unipolar

motors - connect the black wire to ground, brown to 1Y, red to 2Y, white to 3Y,

and green to 4Y.

The

motor power supply is connected via the decoupling RC circuit to Vcc2. One should use a small

resistor for current limiting even though you do not need any voltage drop for

5V motors. When calculating the resistance

of this resistor, keep in mind that the circuit activates two phases at a

time. As you can use only ¼ watt

resistors on the breadboard; connect several resistors in parallel to get the

appropriate wattage. And, as these

resistors may heat up, position them few mm above the board. Check the rating for the capacitor, you will

need at least 15V capacitor for 12V operating voltage. Be careful when the capacitor is charged, do

not re-insert it into the circuit before the charge is dissipated.

Examples of the experiments

you can do with the stepper motor in the lab:

see how the motor work: there are both types type of motor disassembled for study.

measure the DC

operating voltage, resistance and inductance of the

windings

measure the step resolution, accuracy and overshoot

compare their rotating and holding torque

treat the bipolar as a transformer to find phase,

electrical resonance frequency

find mechanical resonance

frequency of the motor itself

leaking flux (the magnetic field outside the motor)

find max pulse rate (maximum angular velocity will be

releted to that).

Stepper motor technology

In

the lab, there is a disassembled two-phase permanent magnet motor (part no.

14769430-00 OY26H PL20S-020-TH03, from a 3.5 floppy diskette drive) for

demo. This motor converts electrical

pulses into discrete mechanical rotational steps. When it takes a step, it exerts maximum field

strength for rotational torque on the leading edge of the applied polarity

changing pulses to the windings. The SN754410 circuit is driven by PB0 and PB1,

as this bit(s) toggle the supply polarity to the respective winding(s). During

the on duty cycle of the pulses, the windings are energized and provide the

holding torque.

The

two windings in the two-section-stator each provide five pole pairs with an

half pole displacement within the section.

The alignment between the two sections is exactly a ¼ of a pole. Each section interacts with its permanent

magnetic rotor with the same number of pole pairs. Like

poles repel and opposite poles attract which is the interaction between the

stator and the rotor. The causes of the

interaction is the polarity change of the winding(s) equals to a ¼ of a pole

rotor movement. If there is five pole

pairs, there would be 20 steps/rev or 18º/step.

Servo motors

The stepper motor drive circuit

can be used for the servomotors. The

only modification needed is the current limiting resistor. Connect the black wire from the motor to 2Y

and the red wire to 4Y. You may find the

pwm.asm and servo.asm programs useful. The pwm is the emphasis of the

servo.asm, naturally, the pwm.asm is a

good place to start.